A Q&A with Kyle of Marathon Fusion

Fusion energy carries the potential to deliver clean, economic, and firm (always available) power to transform how energy gets produced across the world. Though recent milestones have highlighted scientific achievement, commercial development could end up hampered by fuel processing technology that was originally designed for scientific applications, and hasn’t yet seen commensurate progress.

Founded in 2023, Marathon Fusion is taking the challenge head on, building the world’s first fuel systems for commercial fusion energy, and aiming to serve the entire industry with its high-throughput superpermeable pumps to improve fuel processing efficiency.

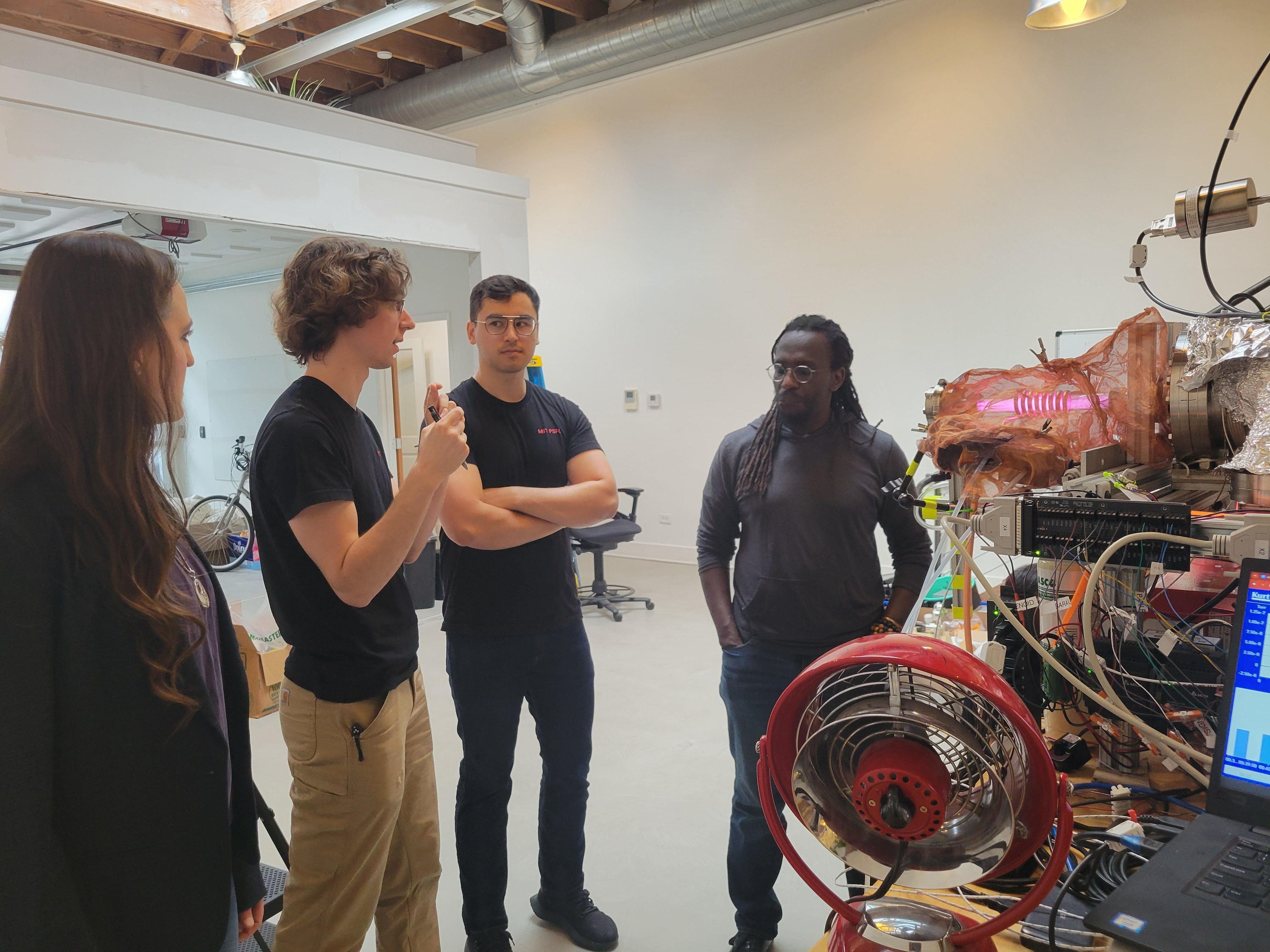

The company developed their first prototype and successfully demonstrated superpermeation last year. Now, they’re working on the challenges of scaling up to meet demand, and validating their performance against requirements set by partners across the fusion ecosystem. We sat down with the Co-founder and CEO, Kyle Schiller, to chat more about the tailwinds, as well as challenges, for the fusion energy ecosystem and what got him so personally motivated to build a company in this space.

What have been the biggest tailwinds for fusion energy over the past few years? How has this catalyzed your company specifically?

What’s most exciting to me on a personal level is just seeing firsthand the number and the quality of people outside of fusion who are beginning to get excited about what we’re building.

A student interested in science who started college in 2021 would have spent that year hearing about Commonwealth Fusion’s 20 Tesla coil and $1.8B fundraise, then about the White House’s milestone program to fund commercial fusion, and then about JET’s record-setting performance just a month later.

Well now it’s summer 2024, and that same student is a rising senior getting hands-on experience at an internship. By next summer, they’ll be graduating into jobs in the private fusion industry at unprecedented rates. That’s where we close the loop from excitement and promise to actually working alongside colleagues we simply wouldn’t have had a decade ago. And the more brilliant and passionate folks we can bring into this industry, the brighter our future looks.

Outside of capital intensity, public perception and timelines for deployment, what have been the biggest challenges for innovation in the nuclear industry?

Fusion devices inherently benefit from scale, which means that cutting-edge research has always had to go big. This severely limits how much you can learn from rapid prototyping on subscale devices, and that in turn really hurts your iteration time.

ITER took that trend to its extreme, and that’s not a path any private company wants to follow. Instead, they’re adopting strategic approaches enabled by advances in the underlying science and technology. Magnetic fusion companies like CFS are using higher field magnets to build a tokamak that achieves better performance at smaller scale, breaking them out of the historical paradigm where you have to go bigger to be better. Other companies like Zap and Realta are pursuing alternative concepts with potentially far greater engineering simplicity, so they can be prototyped more quickly at lower cost. And then you have approaches like laser based fusion which benefit from being relatively modular: you can start with one laser and advance the science and engineering considerably before committing to a large facility.

Outside of the purely technical challenges, I see the history of fusion technology as a history of coordination failures. Fusion power plants are tightly integrated systems: If no one is building a good reactor, there’s no point in building a good fuel system, and the whole industry risks getting bogged down.

We’ve finally broken out of that holding pattern through some combination of scientific and technological achievement and stakeholder alignment, and we’re now seeing that the flipside of that interdependence is a powerful self-improving flywheel.

Scientific advances drive demand for enabling technologies, which in turn derisk the engineering challenges around deployment. The promise of deployment grows the ecosystem, affording the opportunity to make further investments in the scientific basis for novel approaches. From a human capital perspective, recent progress has drawn some really great people to the industry. They’re pushing us even further ahead, and that momentum drives even more interest which keeps fresh talent pouring in.

We’ve made this leap from a zero-sum world of intense competition for limited funding, to a virtuous cycle where the field can grow and thrive, and that’s just an incredible transition in terms of what now feels possible.

What personally got you so motivated to work on the fuel cycle for nuclear fusion plants?

If you woke up tomorrow and found out the fusion industry had demonstrated breakeven, how would you feel? I would celebrate; I would send congratulations; I would feel immense pride at having been some small part of this great achievement… But I would also be kicking myself, and I think anyone with good sense would do the same.

Why? Because we’ve spent the last four decades driving incredible progress on fusion reactor performance, and during that time the technologies required to enable fusion commercialization – to actually put a device on the grid and generate electricity – have not advanced in concert.

We’re reaching a point where the bottleneck to fusion won’t be “will it work?”, but instead “how quickly can we build it?”, and as we approach breakeven, more and more priority will go towards developing these enabling technologies. You have to squint to see it, but the closer we get, the more obvious this dynamic becomes.

Of those enabling technologies, the fuel cycle may be the most crucial of all. The better you are at exhaust processing, the more viable your plant will be in terms of economics, ease of licensing, and scalability. Fuel cycles are what we call a concept-agnostic technology, which means they can support the entire industry regardless of pathway. That approach grows the market we can sell into, but what’s even more important is that by building something general purpose, we can start working on commercial systems right now, even before power plant designs are finalized. We can take a peek over the horizon and start building the future today.